Introduction

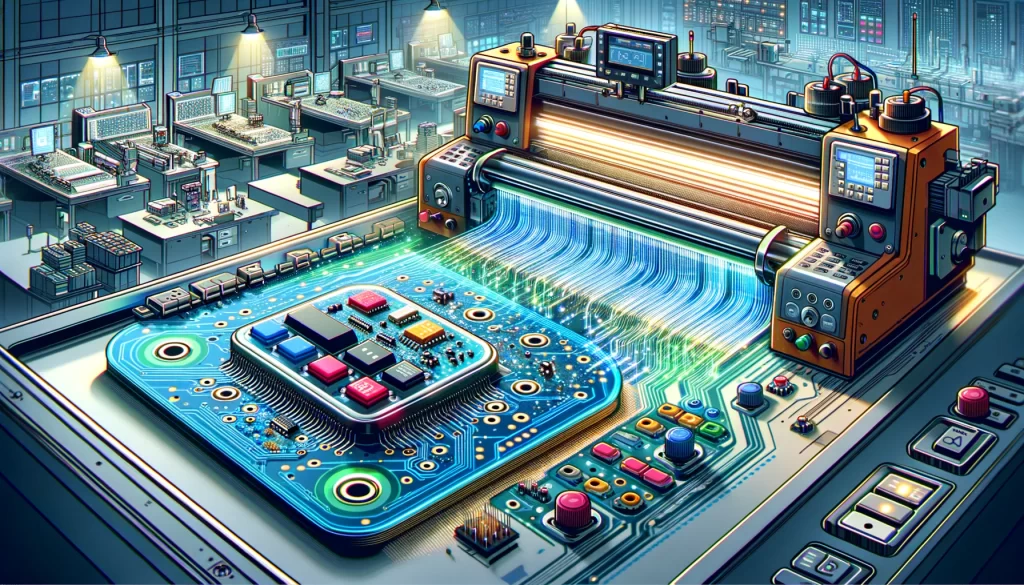

Hey there, manufacturing aficionados! Today, let’s delve into an innovation that’s revolutionizing the world of membrane switch manufacturing: digital printing. Gone are the days of limited color palettes and design constraints. With digital printing, the possibilities are as vast as your imagination.

The Digital Printing Revolution

A New Era in Manufacturing: Digital printing has changed the game in membrane switch production. It allows for high-resolution, intricate designs and a rainbow of colors, all with the precision that modern electronics demand.

Why It’s a Big Deal: In an industry where customization and aesthetic appeal are increasingly important, digital printing offers unparalleled flexibility and efficiency.

The Technical Perks of Going Digital

Precision and Quality: Digital printing excels in delivering crisp, clear graphics, vital for the detailed interfaces of membrane switches.

Speed and Efficiency: Say goodbye to long setup times and hello to faster turnaround. Digital printing streamlines the production process, allowing for quicker responses to market demands.

Customization at Its Finest

Endless Design Possibilities: With digital printing, you’re not limited to a handful of colors or basic patterns. You can bring complex, multi-colored designs to life with ease.

Tailoring to Client Needs: Whether it’s a unique color scheme for a brand or a specific user interface design, digital printing makes it all possible without significant additional costs.

Cost-Effectiveness and Sustainability

Reducing Waste: Digital printing is not just about aesthetics; it’s also an eco-friendly choice. It minimizes waste by printing precisely what’s needed, reducing excess material use.

Cost Savings: Less waste means lower costs. Plus, the efficiency of digital printing reduces labor costs and streamlines the production process.

Integrating with Other Technologies

Combining Forces: Digital printing isn’t just a standalone marvel. It works hand-in-hand with other technologies like touchscreens and LED lighting, enhancing the overall functionality of membrane switches.

The Impact on Durability and Longevity

Long-Lasting Impressions: Digital printing isn’t just skin deep. The inks and processes used ensure that the graphics are as durable as they are beautiful, standing up to frequent use and cleaning.

Real-World Applications

From Concept to Reality: Let’s explore some case studies where digital printing has transformed membrane switch designs, bringing complex concepts to life in practical, everyday products.

Overcoming Challenges

Addressing the Skeptics: Yes, new technologies come with questions. How do we ensure color accuracy? What about wear and tear over time? We’ll delve into how digital printing meets and overcomes these challenges.

Looking Towards the Future

The Next Frontier in Printing: The future looks bright for digital printing in membrane switch manufacturing. As technology evolves, we can expect even more advancements in print quality, speed, and sustainability.

Conclusion

Digital printing in membrane switch manufacturing is more than a technical advancement; it’s a gateway to creativity and innovation. As manufacturers and designers, it opens up a world of possibilities, allowing us to meet the ever-growing demand for customized, high-quality products. The future is colorful, and it’s being printed digitally!