Introduction

Hello, product designers and manufacturing mavens! In our constant quest for durability and functionality, waterproofing membrane switches has become a hot topic. Let’s plunge into the world of waterproofing techniques that are keeping our membrane switches safe from the dreaded enemy: water.

The Why and How of Waterproofing

Understanding the Need: In environments from kitchens to outdoor control panels, water is a constant threat to the functionality of membrane switches. Waterproofing isn’t just a feature; it’s a necessity.

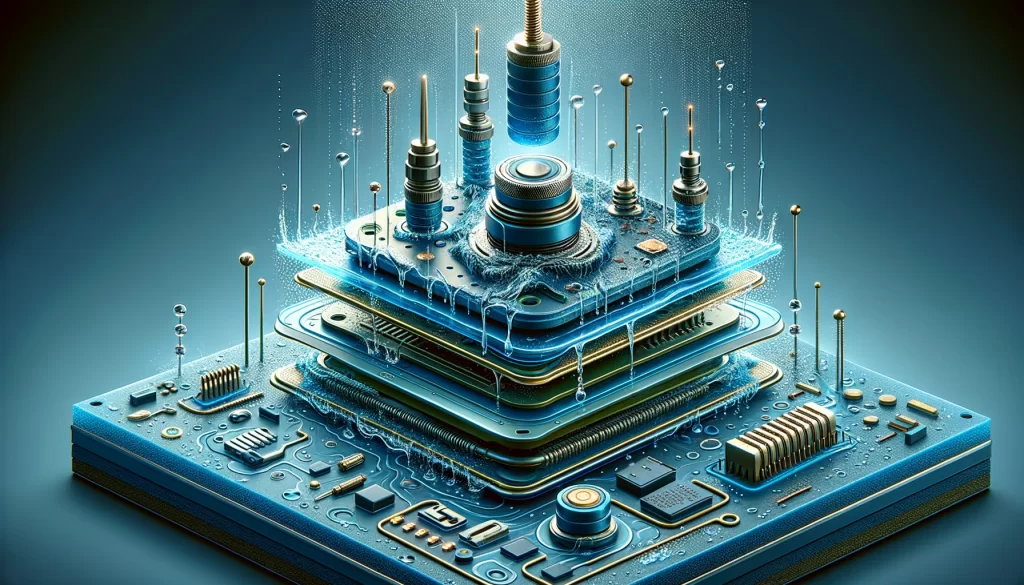

Basic Science Behind Waterproofing: At its core, waterproofing involves creating a barrier that prevents water molecules from penetrating the switch, thus protecting its electrical components.

Techniques that Keep the Water Out

Sealing the Deal with Gaskets: One of the primary methods is the use of gaskets. These can be made from silicone or other flexible, water-resistant materials, forming a tight seal around the switch.

Material Matters: Using water-resistant materials for the switch’s overlay, such as polyester, which is less likely to absorb moisture than polycarbonate.

Advanced Waterproofing Strategies

Encapsulation is Key: This involves encasing the entire switch in a waterproof material. It’s like putting a raincoat around the switch – effective but requires precision in design.

Surface Coatings: Applying a thin, water-repellent coating to the surface of the membrane switch. Think of it as an invisible shield against water.

Design Considerations for Optimal Waterproofing

Balancing Act: The challenge is to make the switch waterproof without compromising on tactile feedback or functionality.

Customization for Different Environments: The degree of waterproofing needed can vary. A switch for a marine device, for example, needs more rigorous waterproofing compared to one used in a kitchen appliance.

The Impact on Durability and Longevity

A Longer Life: Waterproofing significantly extends the life of membrane switches, especially in harsh environments.

Reliability is Key: A well-waterproofed switch ensures consistent performance, which is crucial in critical applications like medical devices or industrial machinery.

Real-World Applications: Waterproofing in Action

Case Study: Outdoor Kiosks

Outdoor Kiosks: Weathering the Storm

- Overview: A company specializing in outdoor kiosks faced challenges with their membrane switches malfunctioning due to exposure to rain, humidity, and varying temperatures.

- Challenge: The kiosks were frequently installed in unsheltered locations, making them vulnerable to weather elements. The malfunctioning due to water exposure led to maintenance issues and user dissatisfaction.

- Solution: The company employed advanced waterproofing techniques in the membrane switches. This included using silicone gaskets for sealing, encapsulating the switches, and applying water-repellent surface coatings.

- Outcome: Post-implementation, the kiosks showed remarkable resilience against harsh weather conditions. The waterproof membrane switches significantly reduced maintenance costs and improved user experience, leading to a boost in customer confidence and an increase in orders for outdoor kiosks.

Medical Industry Insights

Medical Industry: Ensuring Sanitation and Cleanliness

- Overview: A manufacturer of medical diagnostic equipment was seeking to improve the sanitation of their devices, particularly the membrane switches used on the equipment surface.

- Challenge: The equipment needed frequent cleaning and sterilization to prevent contamination. Traditional membrane switches were not standing up well to the repeated use of harsh cleaning agents and sterilization processes.

- Solution: The company incorporated waterproof membrane switches designed specifically for the medical environment. These switches were made with materials resistant to chemicals and capable of withstanding rigorous cleaning. The switches were also designed with a seamless surface to prevent the accumulation of dirt and microbes.

- Outcome: The waterproof membrane switches greatly enhanced the sanitation aspect of the medical equipment. They withstood frequent cleaning and sterilization without degrading, maintaining functionality and tactile response. This led to increased trust among healthcare professionals and compliance with stringent health and safety standards.

Keeping Up with Compliance and Standards

Meeting Industry Standards: Waterproofing isn’t just about functionality; it’s also about compliance with industry standards related to moisture and water exposure.

Future Trends in Waterproofing

Innovation on the Horizon: The future looks bright with advancements in materials science and nanotechnology, promising even more effective waterproofing solutions.

Sustainability in Waterproofing: As we move forward, the focus is also on ensuring that waterproofing techniques are environmentally friendly and sustainable.

Conclusion

As we wrap up our dive into the world of waterproofing in membrane switch design, it’s clear that this is an area where innovation meets practicality. It’s about ensuring that our devices can stand up to the challenges of the real world, come rain or shine. For designers and manufacturers, mastering these techniques isn’t just a skill; it’s a pathway to creating products that are both durable and dependable.