Introduction

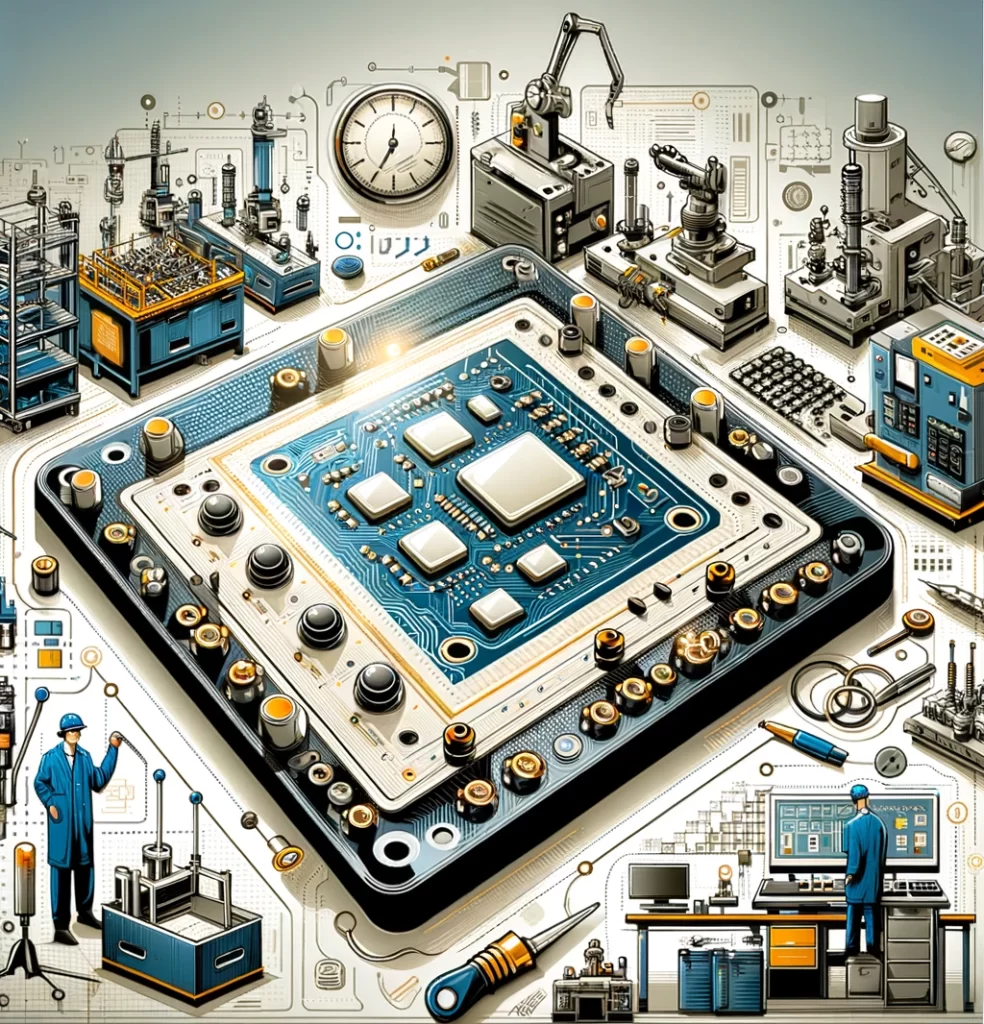

In the manufacturing of membrane switch panels, two crucial factors that determine the success and reliability of the product are its quality and durability. These components are not just about functionality; they are also about providing a dependable user experience over time. This blog post delves into the practices and standards that ensure the highest quality and durability in membrane switch panel manufacturing.

Key Factors in Quality and Durability

1. Material Selection:

- The choice of materials, from the substrate to the overlay, significantly impacts the panel’s lifespan. High-quality materials like polyester (for its resilience) and specialized adhesives (for secure bonding) are essential.

2. Design Precision:

- Detailed and accurate design, considering factors like circuit layout and tactile feedback, plays a vital role in the longevity of the switch panel.

3. Advanced Manufacturing Techniques:

- Utilizing state-of-the-art manufacturing processes ensures consistent quality. This includes precision cutting, accurate printing, and thorough assembly.

4. Integration of Protective Features:

- Features like UV coating, moisture resistance, and temperature tolerance are crucial for panels used in harsh environments.

Quality Assurance Protocols

1. Rigorous Testing:

- Every membrane switch panel should undergo extensive testing, including actuation testing, environmental testing, and life cycle testing, to ensure it meets the required performance standards.

2. Adherence to Industry Standards:

- Compliance with industry standards and certifications like ISO can be a testament to the quality and reliability of the product.

3. Continuous Monitoring and Improvement:

- Ongoing quality control and process optimization are vital in maintaining high standards in manufacturing.

Maintenance and Care

Proper maintenance can significantly extend the life of a membrane switch panel. This includes regular cleaning with appropriate solutions, protecting the panel from extreme conditions, and gentle handling to prevent wear and tear.

Conclusion

Quality and durability in membrane switch panel manufacturing are non-negotiable for ensuring customer satisfaction and product reliability. By focusing on superior materials, precise design, advanced manufacturing techniques, and rigorous testing protocols, manufacturers can deliver products that not only meet but exceed expectations. As technology evolves, so do the standards for quality and durability, and staying ahead in this aspect is crucial for the success of any product in this competitive market. Remember, a durable and high-quality membrane switch panel is not just a component; it’s a commitment to excellence.