Introduction

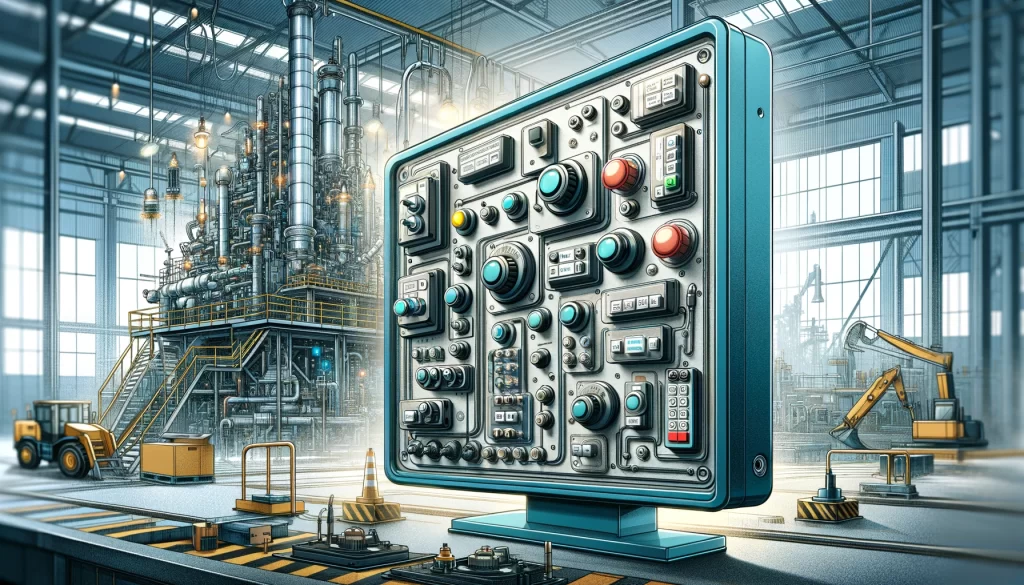

In industrial settings, safety is paramount. Membrane switches play a crucial role in ensuring the safe operation of machinery and equipment. This blog discusses the significance of membrane switches in industrial safety, a vital aspect for companies like ElastoKey that are involved in their production.

Importance of Membrane Switches in Industrial Safety

- Reliability: Membrane switches are known for their reliability, crucial in environments where a malfunction can lead to safety hazards.

- Durability: They are designed to withstand harsh conditions, including exposure to chemicals, extreme temperatures, and physical wear.

- Customizability: Membrane switches can be customized with specific features like emergency stop buttons, making them ideal for safety-critical applications.

Design Features Contributing to Safety

- Clear Labeling and Color Coding: Ensures that operators can quickly identify and access necessary controls, especially in emergency situations.

- Tactile Feedback: Provides physical confirmation of activation, important in noisy industrial environments where auditory signals may be missed.

- Ease of Cleaning and Maintenance: Reduces the risk of malfunction due to dirt or debris.

Applications in Industrial Safety

- Emergency Stop Switches: Quick and easy access to stop machinery in case of an emergency.

- Control Panels for Heavy Machinery: Customizable to include safety-related functions specific to each piece of equipment.

- Hazardous Environment Controls: Designed to function reliably in potentially explosive or corrosive environments.

Incorporating Safety Standards

- Adherence to international safety standards, such as ISO and ANSI, is essential.

- Conducting regular safety audits and compliance checks.

Advancements and Innovations

- Smart Technologies: Integration with smart systems for automated safety alerts and responses.

- Improved Materials: Research into new materials that enhance the durability and reliability of switches in extreme conditions.

Conclusion

Membrane switches are more than just input devices; they are critical components in maintaining industrial safety. Their design, customization, and reliability are key factors in preventing accidents and ensuring safe operations. For manufacturers like ElastoKey, understanding their role in safety is crucial for developing products that meet the stringent demands of industrial applications.