Introduction

At ElastoKey, we believe in transparency and educating our clients about our manufacturing processes. This deep dive into the manufacturing process of membrane switches is designed to give our B2B clients and wholesalers a comprehensive understanding of how these intricate components are created.

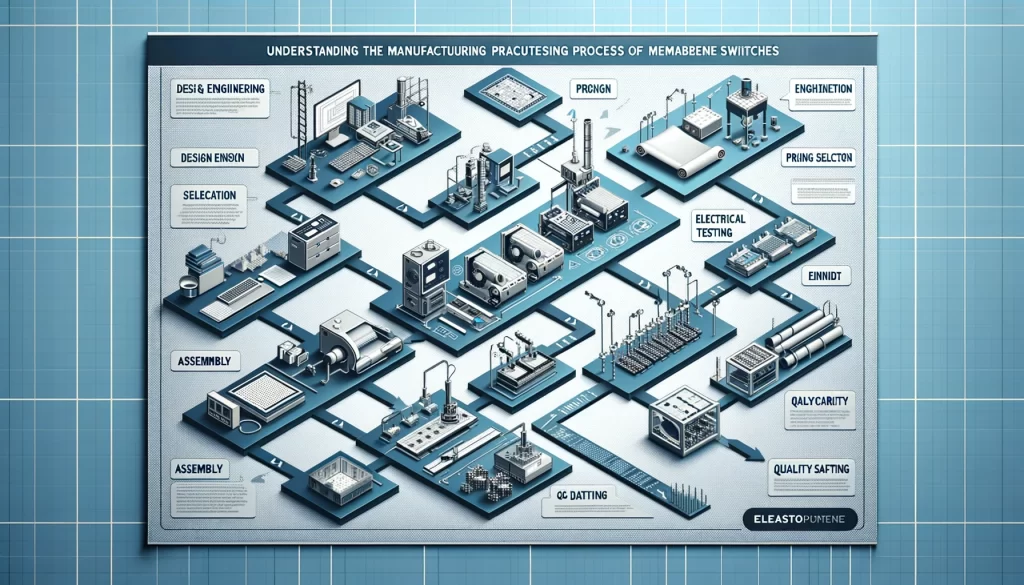

Step-by-Step Manufacturing Process

1. Design and Engineering

The process begins with design and engineering, where we collaborate closely with clients to understand their specific needs. This stage involves creating detailed drawings, selecting materials, and planning the circuit layout.

2. Material Selection

Quality starts with the right materials. We select high-grade materials that meet both the functional and aesthetic requirements of the project, such as polyester, polycarbonate, and adhesive layers.

3. Printing and Cutting

The graphic overlay, which is the interface between the user and the device, is printed and cut. We utilize advanced printing techniques to ensure durability and clarity of the graphics.

4. Assembly

This stage involves layering and assembling the various components of the membrane switch. This includes the placement of domes for tactile feedback, the spacer layer, and the circuit layer.

5. Electrical Testing

Each membrane switch undergoes rigorous electrical testing to ensure functionality and reliability. This step is crucial in maintaining the high-quality standards ElastoKey is known for.

6. Quality Assurance

Quality assurance is integral at every stage, but a final comprehensive check is conducted to ensure that each switch meets our strict quality criteria and the specific requirements of our clients.

7. Packaging and Dispatch

Once approved, the membrane switches are carefully packaged to prevent damage during transportation and dispatched to our clients.

Why the Manufacturing Process Matters

Understanding the manufacturing process is crucial for our clients. It helps in:

- Ensuring Quality: Knowing how these switches are made assures clients of the quality and reliability of the product.

- Customization: Understanding the process allows for better customization according to specific needs.

- Trust Building: Transparency in the manufacturing process builds trust between ElastoKey and our clients.

Conclusion

The manufacturing process of membrane switches is intricate and requires precision and expertise. At ElastoKey, we’re committed to delivering high-quality, custom membrane switches. Understanding these processes helps our clients appreciate the value and quality of the products they are investing in, ensuring a successful partnership.